What is AISI 4140 Material

AISI SAE 4140 alloy steel is a chromium molybdenum alloy steel specification widely used in general purpose high tensile steel for components, like axles, shafts, bolts, gears and other applications. Similar to alloy grade AISI 4130 chrome moly alloy steel but with a slightly higher carbon content. The higher carbon content of AISI 4140 steel gives greater strength and heat treatment capabilities in comparison to AISI / ASTM 4130 alloy steels, however it does have inferior weldability characteristics.

4140 steel is widely used to produce cylinder piston rod or hard chrome hollow bar

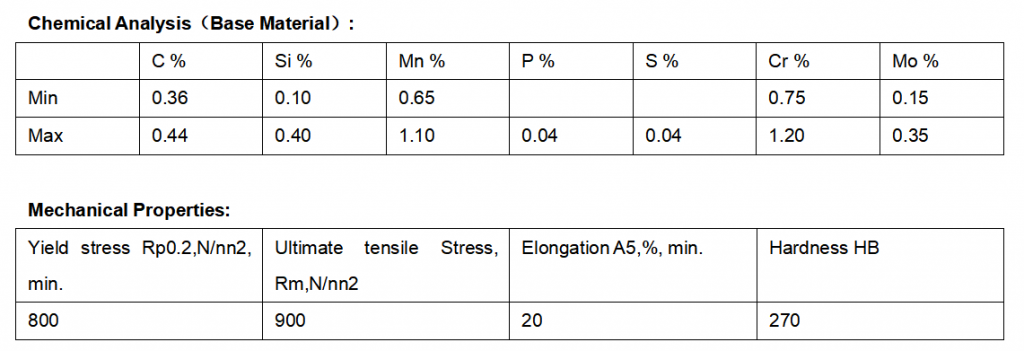

Common 4140 Steel Specifications

AISI 4140 Steel Grade Heat Treatment

- Annealing

Heat ASTM 4140 steels to 800 oC – 850 oC, hold until temperature is uniform throughout the section and cool in furnace. - Normalizing

Heat steel alloy 4140 to 870 oC – 900 oC, hold until temperature is uniform throughout the section, soak for 10 – 15 minutes and cool in still air. - Tempering

Re-heat 4140 grade steel to 550 oC – 700 oC as required, hold until temperature is uniform throughout the section, soak for 1 hour per 25 mm of section, and cool in still air.

Hardening of AISI Alloy Steel 4140

AISI alloy 4140 steel bar, plate and square can be hardened by cold working, or heating and quenching.

SAE 4140 alloy steel is usually supplied ready heat treated to hardness in 18-22 HRC. If further heat treatment is required, then heat to 840 oC – 875 oC, hold until temperature is uniform throughout the section, soak for 10 – 15 minutes per 25 mm section, and quench in oil, water, or polymer as required.